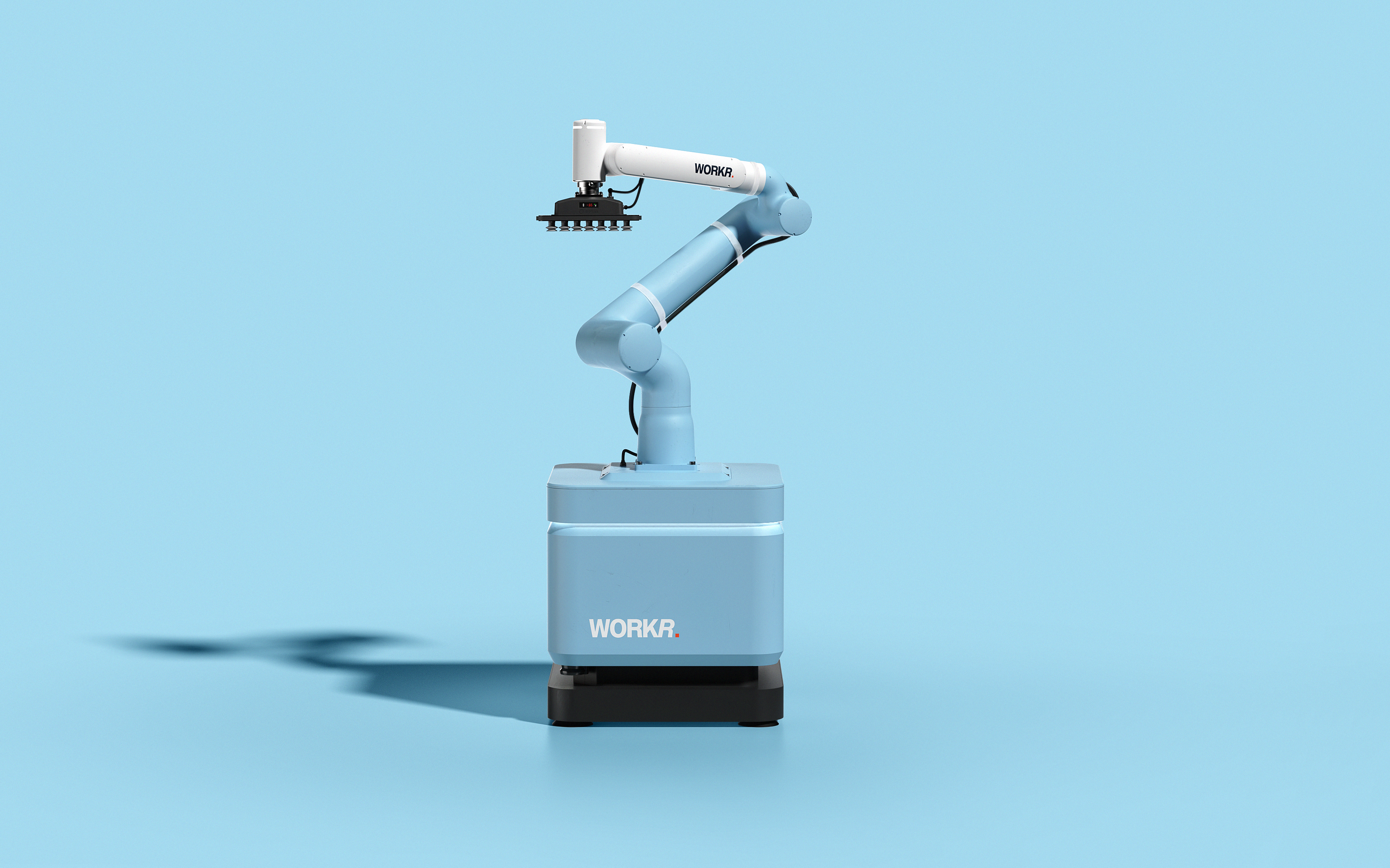

Reliable Manufacturing Workers

Fill your most demanding roles with Workr

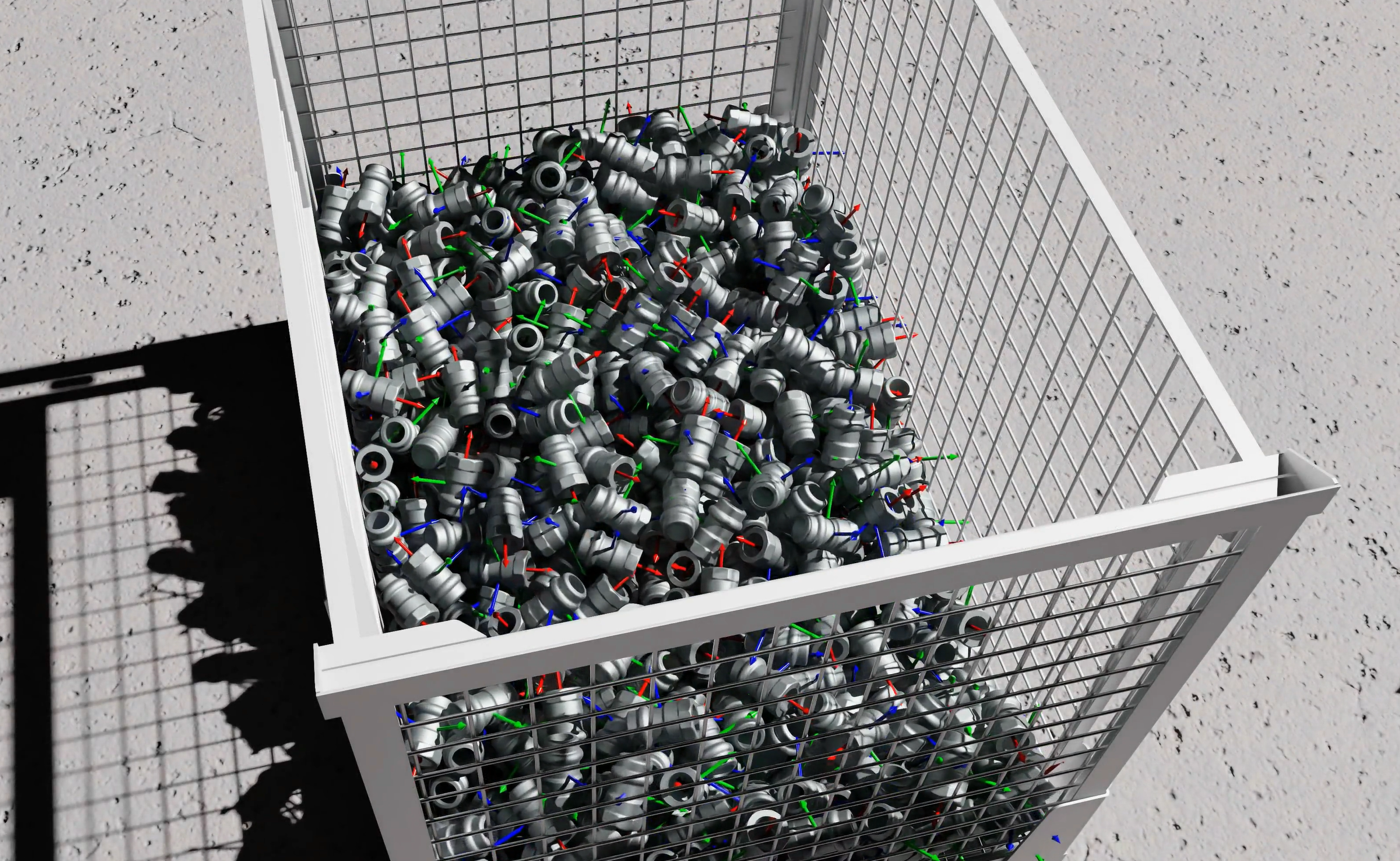

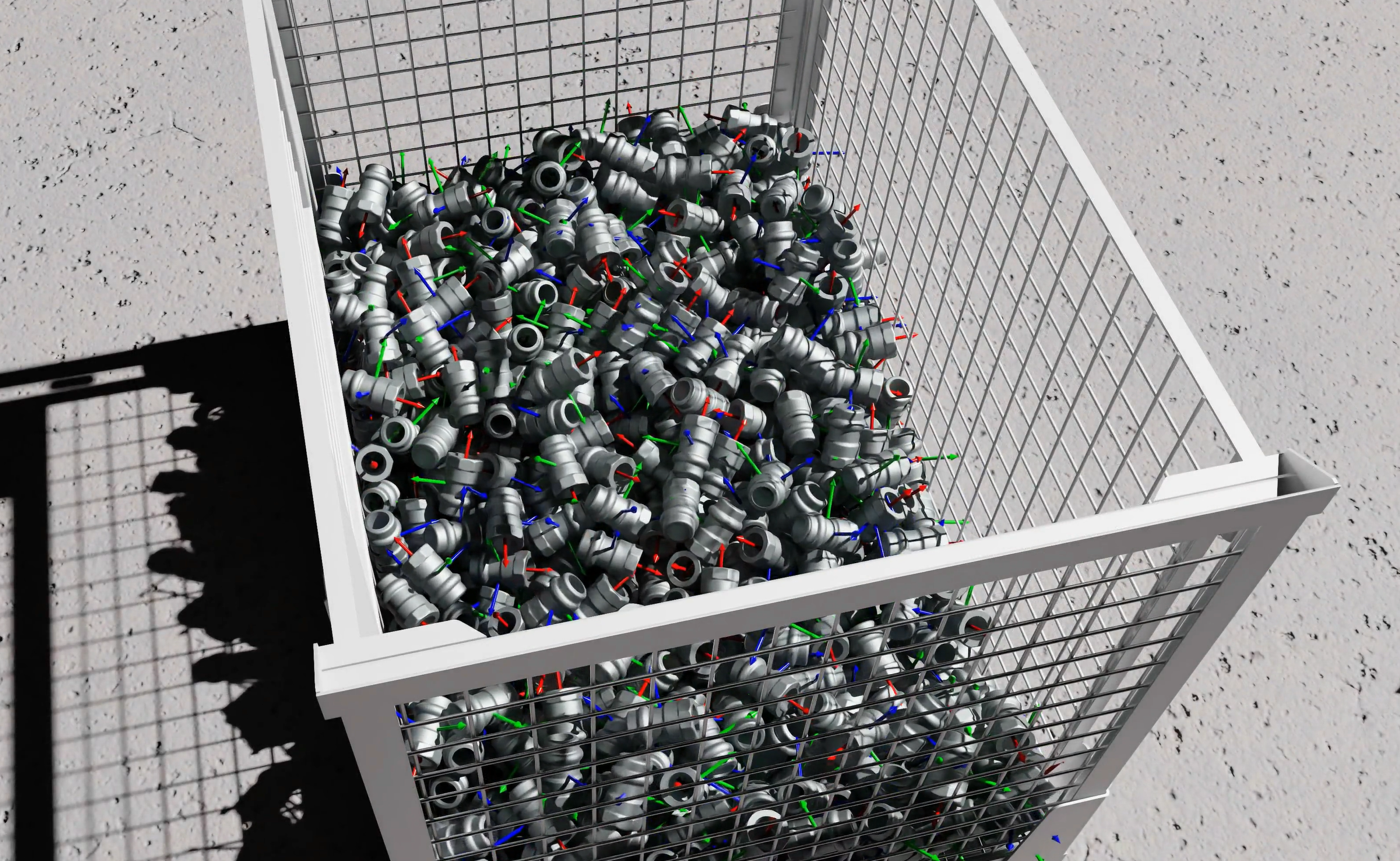

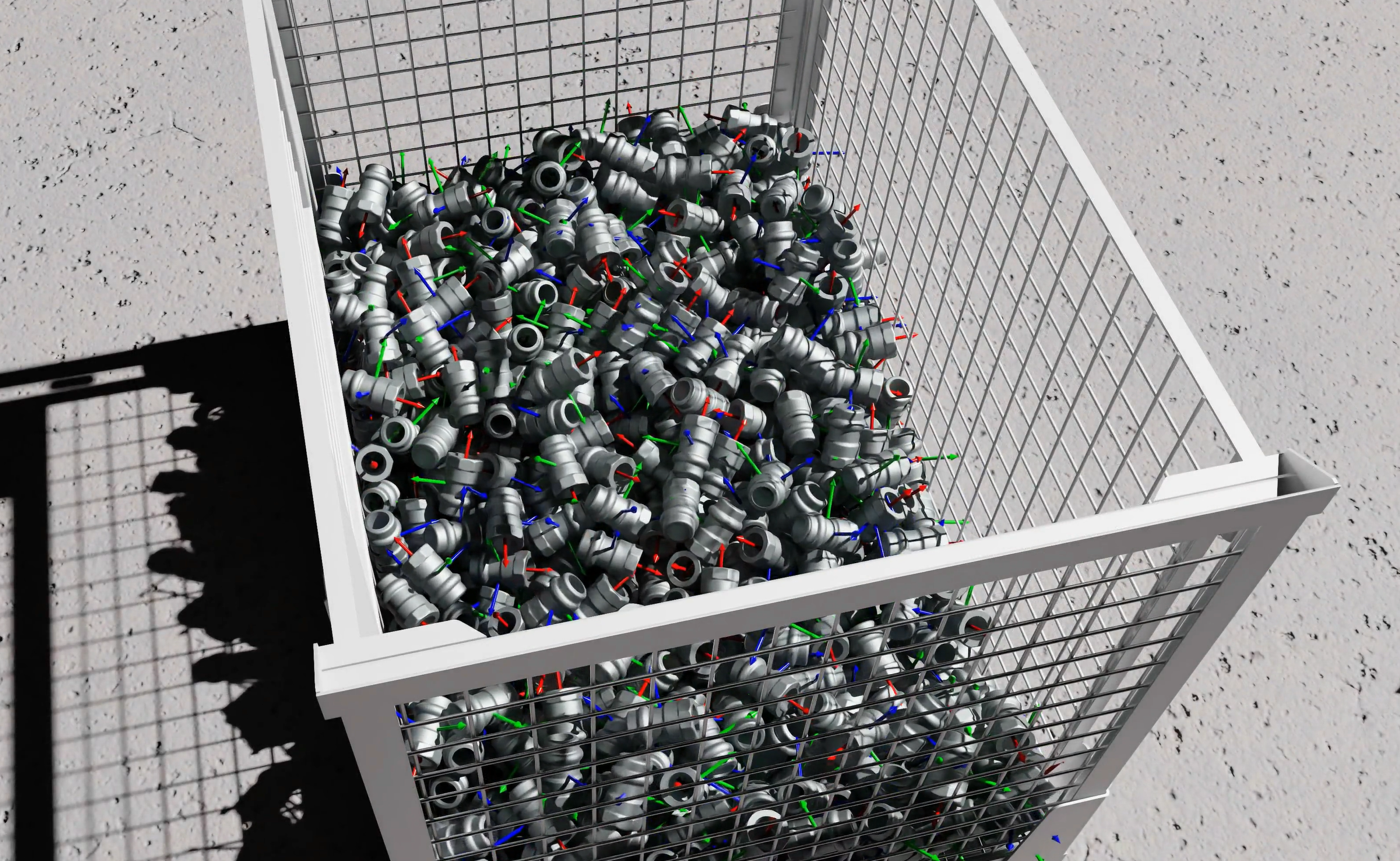

Built for High-Mix

Changes parts in minutes, not hours. No reprogramming between runs.

$25/hr All-In

No capital outlay. No integration fees. No surprises.

24/7 Uptime

Runs every shift with industry-leading reliability

No Long-Term Contracts

Scale up or down as your demand changes

If This Feels Familiar, You’re Not Alone

Hiring Treadmill

You post the job, interview, train, but staff don't stay.

Vacant Roles

Repetitive, physically demanding roles are hard to fill.

Missed Output

Labor gaps quietly become production delays.

Empty Shifts

Second and third shifts remain consistently difficult to staff.

Meet Your Newest Team Member

A Workr Built for the Manufacturing Jobs You Need Done

Consistent, Every Shift

Same quality any time of day.

Your Team Stays in Control

Simple tablet interface your floor operators can manage. No robotics degree required.

High-Mix Manufacturing

Workr adapts to your processes and can switch between parts in minutes without reprogramming.

Scales With Your Business

Ramp up for rush orders, scale back when needed. Flexibility that matches how manufacturing actually works.

Workr fills physically demanding, repetitive, and night-shift roles without hiring, training, or turnover.

One Hourly Rate. No Hidden Fees

Built for Manufacturing Reality

Uptime & Reliability

"What if it goes down?"

Workr runs locally on your floor with no cloud dependency for core operations. If our servers go offline, your system keeps running, and with 24/7 support from US-based engineers who've worked manufacturing floors themselves, you're never stuck waiting.

Data Privacy

"Is my IP safe?"

Your parts, your data, your floor. Workr never trains AI models on your proprietary images. Camera data stays on-site unless you explicitly authorize sharing. We'll sign your NDA before the first site visit.

Operator Control

"Can my team actually run this?"

Yes, and fix most issues themselves. Our interface shows what's happening and why. When something stops, your floor team sees the cause and the fix, not just a "Call Support" button. We want your team confident, not dependent.

Flexibility

"What if demand drops?"

Scale back with 30 days notice. No penalties, no stranded assets and no long-term contracts. We succeed when you succeed, if Workr isn't earning its keep, you shouldn't be paying for it.

1

Discovery Call

Tell us about the shifts that are hard to staff, the tasks that burn people out, and where your production bottlenecks live. We'll be honest about whether Workr is a fit, and if it's not, we'll tell you.

2

Your Solution

Our team configures the right robotic worker for your specific tasks, programs the workflows, and handles all the integration details. We show you exactly what to expect including cycle times, reach and integration points before anything ships.

3

Deployment

We install on your schedule to help minimize disruption. Your team trains on the tablet interface in a few hours, we stay until you're confident. 24/7 access to US-based engineers. Proactive maintenance. Regular optimization reviews.

Industrial System Integrator Lead

Cool

Cool

Cool

Cool

Cool

Industrial System Integrator Lead

Edge Deployment & Infrastructure | High Ownership & Technical Leadership

Location: Mountain View, CA (with significant travel to customer sites)

Compensation: $150,000 – $180,000 + equity (based on experience)

Travel: 30–50%, including extended on-site deployments

We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal, it's the starting point.

As the Industrial System Integrator Lead, you are the field general responsible for the physical realization of our AI. You will lead the effort to integrate our high-level software stack with industrial hardware, PLCs, and safety systems. You aren't just installing robots; you are designing the architecture that allows SOTA AI to survive and thrive in the chaos of a real factory.

What You'll Do

- Lead the end-to-end integration of the Workr AI platform with industrial robot arms (ABB, Fanuc, Kawasaki, etc.) and peripheral hardware.

- Design and implement communication protocols between our edge compute and factory-floor infrastructure (EtherNet/IP, Profinet, Modbus).

- Architect safety-rated control systems, ensuring all deployments meet RIA/ISO standards while maintaining high performance.

- Lead on-site commissioning and deployments, managing everything from electrical panel integration to final sensor calibration.

- Develop "Sim-to-Real" pipelines in collaboration with Simulation Engineers to ensure physical deployments match virtual models.

- Troubleshoot complex "ghost in the machine" issues, hardware timing jitter, network latency at the edge, and EMI in harsh environments.

- Build the integration playbook: Create the standards and documentation that will allow us to scale from one site to one thousand.

Who You Are

- 4+ years of experience in industrial automation and systems integration.

- Education: Bachelor's degree or trade certification in Mechatronics, Electrical or Mechanical Engineering, or related experience in the field.

- Robotics Native: Extensive experience with industrial robot programming and the integration of End-of-Arm Tooling (EOAT).

- Master of the Industrial Stack: Deep expertise in PLC programming, control systems, safety control and industrial networking.

- Hands-on Leader: You are as comfortable red-lining an electrical schematic as you are leading a technical review with customer stakeholders.

- Industrial Compute: Unlike traditional integrators, you are comfortable in a terminal and can navigate a modern software stack to bridge the gap between IT and OT.

- Safety-Minded: Familiarity with industrial safety standards (OSHA, NFPA 70E/Arc Flash, Lockout/Tagout, ANSI/RIA). Certifications such as OSHA 10/30 are a plus.

- Grit: You thrive in the challenge of the factory floor and are ready for significant travel to ensure our robotic workforce is successfully deployed.

Physical Requirements

- Ability to work in active industrial environments, including lifting up to 50 lbs, and working around heavy machinery.

Why Join Us

- Direct the physical rollout of the world's most advanced industrial AI.

- High ownership and autonomy where your deployment strategies define our scalability.

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering.

- Join a rapidly growing company with huge future scope and a mission to win for American manufacturing.

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup.

- Comprehensive health insurance.

Your work is the final, critical step in the chain. You take the AI out of the lab and put it to work. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Project Manager

Cool

Cool

Cool

Cool

Cool

Project Manager

Automation Deployment & Customer Success | High Ownership & Strategic Impact

Location: Mountain View, CA

Compensation: ~$100,000 + equity; higher for candidates with senior-level experience in industrial automation

We are building the largest industrial robotic workforce to help revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots.

To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal, it's the starting point.

As a Project Manager at Workr, you are the primary engine behind our customer success. You will own the project lifecycle from initial quote handoff to final site acceptance. You aren't just tracking tasks; you are the bridge between our high-level physical AI research and the high-stakes reality of the factory floor.

You will lead cross-functional teams of robotics, software, and electro-mechanical engineers to ensure our systems are delivered on time, within scope, and above expectations.

What You'll Do

- Lead the Project Execution Process (PEP): Own the full project lifecycle, including scope definition, risk mitigation, timing, cost, and quality control.

- Serve as the Customer's Main Point of Contact: Facilitate the design and build process, ensuring transparency and satisfaction through regular status updates and site visits.

- Orchestrate Cross-Functional Teams: Act as the "driving force" for the team, promoting cooperation and resolving roadblocks across hardware, software, and deployment domains.

- Manage Financials & Budgets: Maintain an in-depth understanding of the financial health of each project, ensuring we hit profitability and resource utilization targets.

- Drive Risk Management: Proactively identify, qualify, and mitigate project risks to ensure 99.99% reliability in harsh industrial environments.

- Establish Site Acceptance: Coordinate final testing and handover from commissioning to the customer, ensuring all contractual and safety standards are met.

- Continuous Improvement: Capture lessons learned after every deployment to refine our platform and scale our workforce faster.

Who You Are

- Bachelor's Degree in Engineering, Business Administration, or equivalent combination of experience.

- 4+ years of experience in Project Management, ideally within industrial automation, deployed systems, or product manufacturing.

- The "Maker" Mindset: You understand the technical nuances of the "build" and aren't afraid to get on the factory floor to understand a hardware constraint or a deployment hurdle.

- Master of the Critical Path: Comprehensive understanding of project management tools (MS Project, etc.) and best practices in change management.

- Expert Communicator: Ability to translate complex technical challenges into clear project milestones for both internal engineers and external stakeholders.

- Proven Negotiator: History of managing customer contracts, resolving conflicts, and building long-term trust and commitment.

- Thrives in High-Stakes Environments: You enjoy the pressure of moving projects from a "lab setting" to a live production environment.

- Safety-Minded: Familiarity with industrial safety standards (OSHA, ANSI/RIA, risk assessments) preferred.

- Travel: Willingness to travel to customer sites as required to ensure successful deployment and relationship management.

Why Join Us

- Lead the deployment of technology that is actively revitalizing American manufacturing.

- High ownership and autonomy where your management style directly influences our pace of innovation.

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering.

- The opportunity to work on cutting-edge physical AI with direct, real-world impact.

- Join a rapidly growing company with massive future scope.

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup.

- Comprehensive health insurance.

Your role isn't about moving tickets in a dashboard; it's about moving robots onto factory floors. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Senior Robotics Engineer

Cool

Cool

Cool

Cool

Cool

Senior Robotics Engineer

Physical AI/Robotics at the Edge | High Ownership & Product Influence

Forget robotic lab projects folding laundry. We're shipping a revolution. We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal—it's the starting point.

As a Senior Robotics Engineer, you will work across a wide range of challenges spanning perception, planning, control, machine learning, applications, and drivers. You will play a key role in designing, building, and maintaining production-quality robotics software that enables our systems to operate reliably in the real world. You won't just influence a product; you'll collaborate closely with customers to build the infrastructure of a new industrial era.

What You’ll Do

- Contribute flexibly across the stack, from low-level drivers and control to high-level planning, perception, and applications

- Design, implement, and maintain robust, scalable software for production robotic systems

- Work with product and customer teams to quickly understand requirements and translate them into practical engineering solutions

- Optimize algorithms and system architecture to ensure high performance and reliability in real-world deployments

- Debug complex system-level failures spanning hardware, perception, and control

- Test, develop and train the latest VLA, VLM, AI and ML technologies

- Contribute to the overall product strategy and help define technical priorities across the stack

Who You Are

- PhD or equivalent experience in core robotics skills such as; applied perception, control, motion planning, machine learning, or physical interaction

- 5+ years of professional experience in the software industry

- Strong software development background, with experience writing production-quality software

- Have worked on deployed hardware systems (including both sensing and actuation) where reliability and robustness are critical

- Experience contributing to large, long-lived products and tech stacks

- Comfortable working across multiple domains, able to quickly pick up new technologies and frameworks

- Understands the importance of customer requirements and balances technical excellence with usability and business needs

- Thrives in fast-moving, high-ownership environments and enjoys solving complex, cross-disciplinary problems

- Willing to jump in and own both large and small problems across hardware and software domains, everything from loose bolts to top level platform architecture

Why Join Us

- Build the core technology powering the future of intelligent manufacturing automation

- High ownership and autonomy where your contributions directly influence our system architecture and product direction

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering

- The opportunity to work on cutting-edge problems with direct real-world impact

- Join a rapidly growing company with huge future scope

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup

- Comprehensive health insurance

Your code won't be living in the cloud controlling widgets; it will command machines on the factory floor. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Forward Deployed Engineer

Cool

Cool

Cool

Cool

Cool

Forward Deployed Engineer (multiple roles & locations)

Physical AI/Robotics at the Edge | High Ownership & Product Influence

This role is for the SI engineer that wants to work on the next generation of industrial automation not legacy. We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal—it's the starting point.

As a Forward Deployed Engineer, you are the bridge between our revolutionary AI platform and the physical reality of our customers' factories. You are the hands-on expert on the front lines, integrating our platform across multiple industrial robot form factors (industrial, cobot, delta, SCARA, AMR, humanoid). You won't just be configuring systems; you'll be solving complex, real-world integration challenges, ensuring our solutions achieve the brutal reliability our mission demands and delivering massive value directly to our customers.

What You’ll Do

- Integrate our platform with a wide variety of industrial robots (ABB, Fanuc, Yaskawa, Kawasaki, Universal Robots) and control systems (PLCs).

- Lead on-site deployment and integration of our AI-powered robotics systems at customer facilities across the country.

- Collaborate closely with the core robotics and software engineering teams, providing critical feedback from the field to drive product improvements and new features.

- Set up, calibrate, and validate computer vision systems, grippers, computer and network hardware/software.

- Serve as the primary technical point of contact for customers during deployment, providing expert-level troubleshooting for mechanical, electrical, and software issues.

- Collaborate closely with the core robotics and software engineering teams, providing critical feedback from the field to drive product improvements and new features.

Who You Are

- 4+ years experience as a Systems Integrator, Automation Engineer, or Controls Engineer in an industrial environment.

- Qualified background in mechanical, electrical, or controls engineering or similar trade/discipline.

- Experience programming and integrating industrial robots in manufacturing environments (e.g., Fanuc, ABB, Yaskawa, Kawasaki, Universal Robots).

- A natural, tenacious problem-solver who excels at debugging complex electro-mechanical systems on the factory floor.

- Thrives in fast-moving, customer-facing roles and is willing to travel to customer sites to get the job done.

- You are an excellent communicator who can build trust with operators and engineers alike.

- Eagerness to learn new skills across hardware and software platforms.

Why Join Us

- Deploy the core technology powering the future of intelligent manufacturing automation and see your work come to life.

- High ownership and autonomy where your feedback from the field directly influences our product roadmap and customer success.

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering

- The opportunity to work on cutting-edge problems with direct real-world impact

- Join a rapidly growing company with huge future scope

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup

- Comprehensive health insurance

You won't be stuck behind a desk; you'll be on the factory floor bringing intelligent machines to life. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Simulation Engineer

Cool

Cool

Cool

Cool

Cool

Simulation Engineer

Physical AI/Robotics at the Edge | High Ownership & Product Influence

Forget robotic lab projects folding laundry. We're shipping a revolution. We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal—it's the starting point.

As a Simulation Engineer, you will be crucial to accelerating our physical AI development by creating realistic, high-fidelity synthetic environments. You will use state-of-the-art simulation platforms to test, validate, and train our perception and planning systems before they ever touch physical hardware. This is a junior-to-mid-level role perfect for an engineer who wants to specialize in the intersection of robotics, applied AI, and virtual world creation.

What You’ll Do

- Design and program complex synthetic environments to mimic diverse industrial settings and operational scenarios.

- Develop and integrate sim-ready 3D assets (robots, objects, sensors, factory layouts) that accurately represent real-world physics and appearance.

- Work primarily with NVIDIA Isaac Sim to generate vast amounts of synthetic data for training robust machine learning models.

- Utilize and maintain physics engines (like PhysX or Newton) to ensure realistic robot-environment interactions.

- Collaborate closely with Robotics and ML engineers to ensure simulation models and environments meet specific testing and training needs.

- Optimize environment performance and rendering to ensure simulation throughput is high.

- Contribute to the overall product strategy by defining the future of our simulation platform.

Who You Are

- BS in Computer Science, Software Engineering, or related engineering field (or equivalent experience)

- 1-4 years of professional experience in 3D simulation, game development, or 3D world creation

- Proven hands-on experience using NVIDIA Isaac Sim (highly preferred), MuJoCo, Unity, or Unreal Engine for generating simulations and synthetic data.

- Solid background in 3D asset generation, optimization, and integration of models into simulation/game engines.

- Understanding of physics engines and their application in realistic simulation.

- Strong programming skills in Python or C++

- Detail-oriented and obsessed with ensuring the simulated world accurately reflects the physical world.

- Thrives in fast-moving, high-ownership environments and enjoys solving complex, cross-disciplinary problems.

Why Join Us

- Build the core technology powering the future of intelligent manufacturing automation

- High ownership and autonomy where your contributions directly influence our system architecture and product direction

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering

- The opportunity to work on cutting-edge problems with direct real-world impact

- Join a rapidly growing company with huge future scope

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup

- Comprehensive health insurance

Your code won't be living in the cloud controlling widgets; it will command machines on the factory floor. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Frontend Software Engineer

Full Time

Start December 2024

Cool

Cool

Cool

Frontend Software Engineer

Physical AI/Robotics at the Edge | High Ownership & Product Influence

Forget robotic lab projects folding laundry. We're shipping a revolution. We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA’s most advanced compute, state-of-the-art ML models, and real-time robotics systems operating in noisy, harsh, unpredictable environments—where 99.99% completion isn’t the goal… it’s the baseline.

As our Frontend Engineer, you will own the interfaces that operators, engineers, and customers rely on to understand, command, and trust mission-critical robotic systems. You’ll be responsible for building intuitive, real-time UI experiences that bridge the gap between complex physical automation and clear, actionable insight. You will collaborate closely with backend, robotics, and product teams to turn streaming sensor data, system events, and AI outputs into world-class interaction surfaces.

This role is perfect for someone who wants enormous ownership, loves shipping fast, and wants to build products that control real machines moving real atoms—not just pixels.

What You’ll Do

- Build, ship, and maintain core UI surfaces using React (and modern tooling such as Vite, TypeScript, etc)

- Design real-time interfaces for configuring, monitoring and commanding robotic cells

- Collaborate with backend and robotics teams to define APIs, data contracts, and UI-ready schema

- Build operator workflows that are intuitive and robust in chaotic, high-mix manufacturing environments

- Own the frontend architecture and best practices for a fast-moving team

- Bring a product mindset: simplify complexity, eliminate cognitive load, and elevate operator confidence

- Apply design intuition to translate robotics concepts into clear UX metaphors

- Shape the frontend culture, patterns, tooling choices, and overall development experience

Who You Are

- Thoughtful, detail-oriented engineer who cares deeply about clarity and user experience

- Strong experience building production React applications (TypeScript preferred)

- Comfortable owning UI/UX end to end—from design reasoning to implementation to performance optimization

- Ability to work across ambiguous, evolving requirements and turn them into elegant, workable interfaces

- Familiarity with backend APIs, distributed systems, or robotics/automation concepts is helpful (but not required)

- Thrives in high-ownership environments and enjoys collaborating with robotics, ML, and hardware engineers

- Comfortable building both customer-facing surfaces and internal engineering tools

Why Join Us

- Build the UI that brings intelligence, transparency, and control to fleets of real industrial robots

- Own a massive surface area and directly shape how humans interact with next-generation automation

- Work in a collaborative, high-output team solving problems that matter for American manufacturing

- Competitive compensation including salary and meaningful equity

- Create the frontend architecture for a small, high-impact engineering team

- See your work directly influence physical systems deployed into real factories—not just simulated demos

We hire high-caliber individuals. If you don’t meet every requirement but have strong React fundamentals and a deep desire to build world-class interfaces for real-world robotics, we encourage you to apply.

If you’re passionate about shaping how humans command intelligent machines at the edge, we’d love to talk.

Apply now and help us build the future of automation.

Robotic System Integrator

Remote

Flexible hours

Career Growth

Cool

Cool

Robotic System Integrator

Physical AI/Robotics at the Edge | High Ownership & Product Influence

This role is for the System Integrator that wants to work on the next generation of industrial automation not legacy. We are building the largest industrial robotic workforce on Earth to revitalize American manufacturing in the dirty, dull and dangerous tasks.

We are a small team with deep roots in manufacturing, industrial automation and physical AI, and we are tackling one of the most formidable engineering challenges of our time: deploying and orchestrating fleets of intelligent industrial robots at the edge. To do this, we are unleashing the full power of NVIDIA's most advanced compute, SOTA ML models in harsh environments where 99.99% task completion isn't a goal—it's the starting point.

As a System Integrator || Electro-Mechanical Engineer, you will be a core contributor bringing our designs to life—a true multidisciplinary "builder" who can rapidly prototype and test integrated hardware systems. This is a junior-to-mid-level role perfect for an engineer who thrives on taking concepts from CAD to working physical hardware, spanning electrical, mechanical, and software domains. You will be instrumental in the build, deployment, and testing of our physical AI systems.

What You’ll Do

- Design, build, and integrate complex robotic and sensing hardware from conceptual design through to functional, production-ready systems.

- Fabricate, and assemble mechanical systems and components, utilizing tools like 3D printing, laser cutting, machining, and various shop equipment.

- Design and execute electrical integration, including wiring harnesses, power distribution, sensor/actuator integration, and basic PCB design/modification.

- Perform hands-on troubleshooting and root-cause analysis on system-level failures,

- Contribute to CAD modeling, drawings and documentation to ensure manufacturability and system repeatability.

- Develop and run validation and endurance tests for both new and existing hardware in rugged industrial environments.

- Work closely with Software and Robotics Engineers to integrate physical hardware with the software stack and production environments

Who You Are

- Bachelor's degree or equivalent experience in Mechanical, Electrical, Mechatronics Engineering, or a related technical field.

- 1-4 years of hands-on, practical experience in a role requiring multi-disciplinary engineering skills (e.g., robotic installs, PLCs, prototyping, lab/shop experience, personal projects).

- Demonstrated experience via a project portfolio in designing, building, and deploying physical systems, showcasing breadth across mechanical and electrical domains.

- Experience with various manufacturing processes and tools (3D printing, laser cutting, CNC, etc.)

- Proficiency in CAD software (Fusion 360 preferred) and creating technical drawings/schematics.

- Strong practical skills in electrical assembly, soldering, crimping, and wiring.

- Familiarity with microcontrollers (e.g., Arduino, Raspberry Pi) and basic scripting/programming for hardware control (e.g., Python, C/C++).

- A natural, tenacious problem-solver who excels at debugging complex electro-mechanical systems on the factory floor.

- You are an excellent communicator who can build trust with operators and engineers alike.

- Eagerness to learn new skills across hardware and software platforms.

Why Join Us

- Be the critical link translating digital designs into reliable, functional physical AI systems.

- High ownership and autonomy where your contributions directly influence our system architecture and product direction.

- Work alongside a small, high-caliber team of experts in robotics, perception, planning, and systems engineering.

- The opportunity to work on cutting-edge problems with direct real-world impact.

- Join a rapidly growing company with huge future scope.

Benefits

- Competitive compensation including salary and equity in a seed-stage venture-backed startup

- Comprehensive health insurance

Your work will not be theoretical; it will be in the steel and wires that command machines on the factory floor. We're solving brutally hard problems to help American manufacturers win. If you have the grit to ship real-world AI, don't let a checklist stop you from applying.

Let’s See If Workr Fits Your Floor

Every manufacturing operation is different. Tell us about your labor challenges and we'll give you an honest assessment. We're not a vendor, we're a partner in your production.